Ans: The average cost of a reasonable simple staircase is approximately $3,500. However, it is a rough estimate, thus subject to change, depending on the specific needs of a particular person.

How to Make Stairs Easily: A Step-by-Step Guide

Many people buy resale homes, and they don’t like much of the structure! One such area could be the staircase! Or, perhaps, the stairs aren’t in good condition, thus requiring a renovation. Well, whatever your reasons are, in this article, we will learn how to make stairs comfortably without much hassle.

With the right knowledge and practical insights, it will be nothing but a piece of cake. Wooden and concrete, both types of stair-making processes are explained below, step by step. Hence, follow along and read till the end, so that every visitor will appreciate your skills and home aesthetics forever!

Key Takeaways

- Take measurements like total rise and total run so that you can determine the number of risers and treads needed.

- Ensure high-quality lumber to prepare risers and treads in the right shapes and sizes, based on the measurements taken.

- Next, prepare stringers out of large rectangular and flat lumber pieces. Always use a well-maintained circular saw for accuracy in the final structures.

- First, install the stringers and then assemble risers and treads onto it to complete the structure.

- Apply protective coatings and paints to the staircase once it is complete to increase its durability.

How to Make Stairs in Simple Steps

It is easy to learn how to build a staircase, as you just need to follow 10 simple steps. The entire stairs building process includes:

- Measuring the floor-to-floor height

- Dividing the total rise into risers

- Calculating total and unit run

- Figuring out if landings are needed

- Calculating stringer length

- Figuring out how many stringers you need

- Preparation of stringers

- Setting up stringers at the right place

- Securing stringers with risers & treads

- Strengthening the structure with varnish or other protective substances

Furthermore, check out the detailed explanation of each for better clarity.

1. Measure the Floor-to-Floor Height

Firstly, you need to calculate the total rise, near the area where you want your staircase to stand up! So, take your measurement tool, and then find out how much distance you need to cover vertically.

For example, suppose you want to build a flight of stairs to reach your first floor that is 4 feet (1.22 m) above the ground floor. In that case, 4 feet (1.22 m) is the total rise.

2. Divide Total Rise into Risers

As you have calculated the total rise, it is time to divide this measure into smaller, individual units, corresponding to single stairs. The calculation is crucial, as it helps find out how many risers must be in your staircase.

This is the most demanding part of the process. Thus, work with all your attention and take assistance from the experts in the same field to reduce the chances of mistakes and wrong measurements.

The wrong number of stairs can make the flight too steep and thus dangerous to climb! So, decide, keeping in mind that the elevation must be slow and gradual, with the breadth of the tread always more than that of the riser.

3. Calculate Total & Unit Run

Total rise is the measure of the distance you cover vertically with a flight! But that is not all, you also cover some distance horizontally while climbing stairs, which is the total run. When the total run is calculated for a single step, it is called a unit run.

A higher total run ensures that your flight will be comfortable to climb due to being less steep. So, at this stage, figure out how many treads you must use according to your specific total run for an easy flight.

4. See if Landings Required

For a staircase with a high total rise and run, landings are often used to provide different directions to flights. When there is a vertically long distance to cover with a comparatively low space horizontally, stairs have to run in circular, U or L shapes, as the elevation increases, for better space management.

That is where landings, large flat treads, come in handy for maximum space utilisation.

5. Calculate Stringer Length

In the process of making stairs, the next step involves measuring the accurate length of the stringer, which is the structure on which you assemble risers and treads to make steps. To find out how long your stringer must be, calculate the distance diagonally starting from the top stair to the bottom one.

Don’t forget to check that your measurement tool is accurate and not broken. Otherwise, you will end up with inaccurate results, affecting the overall functionality of the final structure.

6. Figure Out Stringer Count

After learning about the right length of the stringer, it is time to figure out how many such frames you need to prepare. There is nothing wrong with having more supporting structures behind the staircase than an insufficient number!

For example, for a lengthy tread, often three diagonal holders are enough. However, there is nothing wrong if you would like to add one more, as per your demands and space requirements!

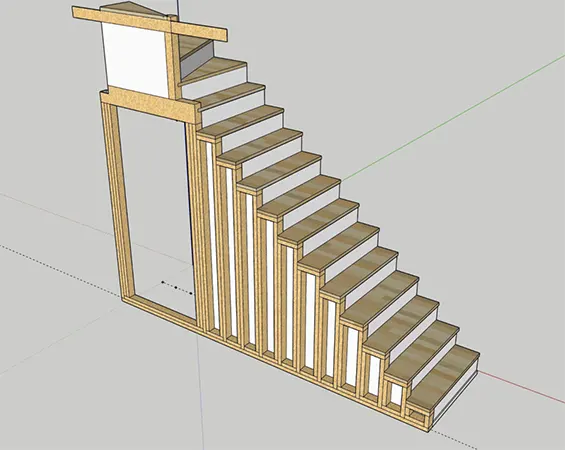

7. Prepare Stringers for Structural Support

It is easy to prepare a stringer by following the steps and instructions mentioned ahead.

- Select a piece of quality lumber that best fits the dimensions of the ideal frame, in your case.

- Mark the unit run and rise on it as per the number of steps you need.

- Cut out the marked portion for a step first, and then test how well it accommodates a riser and a tread. If everything goes well, then proceed further.

- After all marks are removed, don’t forget to adjust both ends of the structure according to the surface where it needs to be installed.

- If the stringer seems 100% compatible, use it as a template to build a second one.

However, in case of inconsistencies, figure out what is lacking and try to fix it while making a new one from scratch.

8. Set Up Stringers at the Right Place

In the process of building staircase, now comes the most important step, which is to install the stringers on which risers and treads will be attached, to provide shape to the overall structure.

During the installation, don’t forget to check that all the stringers are fixed with equal and sufficient space in between. Lacking in ensuring that will lead to uneven weight distribution, weakening one structure more than the other. Over time, the structure will bend downwards in one direction.

9. Secure Stringers with Risers & Treads

Usually, a 1 inch × 6 inch plank is perfect to make the best riser, but you can also adjust dimensions as per your specific needs, as it is not a must! Moving further, as the stringers are secured to the floor and ground, attach all risers and treads to them with screws.

Ensure that no component is left loose, as it will later give way, causing accidents. Once the structure is ready, you can also consider making your staircase more aesthetically pleasing by adding outer stringers to it, even though it is completely optional.

10. Strengthen the Structure with Varnish, Paint, or Sealants

Our discussion on ‘how do I make stairs?’ concludes here! So far, we have elaborated on all the major stages of stair making, and now only the finishing touch is left. So, if you want to add an extra layer of strength to stairs, consider applying varnish. Paint all components with high-quality paint or even use sealants to fill unwanted gaps, if any. Before ending the discussion, consider the following note below.

Note:

You don’t need anything other than the information shared above, even though you want to learn how to build stairs from a deck. The process remains the same, no matter from which location of your house you want to build stairs.

Exclusive Read: Construction Bidding: Learn Meaning, Stages, Elements, Types, and More!

How to Build a Concrete Staircase Step by Step?

There are three major stages of building a concrete staircase, namely planning, groundwork, and pouring with finishing. It might seem a labour-intensive project at first. However, with dedication, you can make it. Consider the following steps to get started.

- Measure Dimensions: Find out the total rise, total run, and width per step. These measures are crucial for starting the concrete stair-making process.

- Decide Stairs’ Number: Consider either the total run or the total rise, and divide it by the standard unit rise, which is 7.5 inches (19.05 cm) per stair. It will provide you with the number of steps you need to cover the elevation gradually. You can decrease the size of the unit rise (7.5 in), but never increase it, as it will make the stairs steeper and thus more prone to accidents.

- Calculate Riser and Tread Sizes: According to the number of steps needed, figure out the height and length of risers and treads, respectively. Suppose you accept the standard unit rise of 8 inches (ca. 20 cm). In that case, your riser height will be 8 inches (ca. 20 cm).

- Find Stringer’s Length: Calculate it diagonally from the upper-right corner of the highest stair to the lower-left corner of the bottom stair.

- Excavate Land: Once key components are measured, it is time to dig the soil out of the ground where the stairs will be built. In this dug-out region, the base will be prepared later.

- Prepare the Form: Mark unit rise and unit run measures on a low-quality lumber board, and then build a formwork with plywood. Afterwards, prepare the required number of risers and attach them to the formwork to develop a frame.

- Lay Sub-base: Prepare the sub-base using the excavated area. Your concrete steps will stand upon this foundation for extra stability. This part is usually prepared by pouring dry gravel and other solid materials into the pit.

- Place the Form: Install the formwork onto the base securely and then build a rebar cage into the frame.

- Mix & Pour Concrete: Rent a small cement mixer and use it to prepare concrete out of a ready-made bag. Pour the concrete mix once ready into the mould and complete the process by smoothing treads. Eliminate uneven spaces early, as it is irreversible once the structure dries out.

Once all is done, wait for the stairs to dry and become completely secured. Ensure animals don’t step on it, damaging the even surface with their paws. Use a protective frame for that purpose if possible.

Also Read: How to Build a Treehouse: Make Memories and a Backyard Escape That Lasts!

Conclusion

So, from the preceding discussion, you must have understood that it is not hard to learn how to make stairs, even though you are not an expert. All you need is the right education and dedication.

However, if you struggle during the process, never hesitate to seek guidance from a professional or a contractor. It might cost you some dollars, but it will save you from ending up with faulty structures!

Also Read: 10 Biggest Construction Companies in the US to Know Before Hiring a Contractor!

FAQs

Q: How Much Does A Simple Staircase Cost?

Q: How Wide Does A Staircase Have To Be In A House?

Ans: For a single person, normally a 2-foot (0.61 m) wide space is enough for going up and downstairs. However, practically, everyone must aim at making it 3 feet (0.91 m) wide so that even two people can use the stairs simultaneously.

Q: How long does it take to build 4 stairs?

Ans: It shouldn’t take more than 2 days at most. Yet, most people with the favourable weather and no other disturbances can end up finishing the build in even less than a day.

Q: Can I Build A Staircase Myself?

Ans: Yes, everyone can build a staircase themselves, provided they have enough time to learn and build. Additionally, you must also be comfortable making mistakes and learning from them if you are a beginner.

Q: What Is The Rule For Making Stairs?

Ans: The basic rule for making stairs is to do your measurements right. Pay complete attention to total rise, total run and length of the tread so that your structure is the most accurate once finalised.